Deep Offshore Technology: Innovations,and Future Trends

Introduction Deep Offshore Technology

This new technology for drilling at greater depth (Deep Offshore Technology) allows the energy market to access massive new oil and gas reserves located deep under the ocean floor. However, the world is continuing to demand energy and deep-sea drilling and offshore production have become lighter, vaulting their sectors more efficiently, safely, and sustainably. In this article, you will find what deep offshore technology has evolved into, deep offshore innovations, the challenges it has encountered, and future trends.

Deep Offshore Technology Evolution

Early Developments (before 1950s)

Early offshore oil drilling started in shallow water on wooden platforms off the coast. Such structures were inherently easily damaged by the heavy ocean conditions and thus limited in their effectiveness.

Famous Scholars and Mottos (From 1970s to Present)

In the 1950s, fixed platforms had been developed for deep-water drilling. By the 1970s, semi-submersible rigs and floating platforms had pushed operational depths over 1,000 feet, making operations more efficient and reliable.

Contemporary Innovations (1990s-Present)

Now, offshore drilling can also go beyond 10,000 feet deep, due to advances in technology such as remotely operated vehicles (ROVs), floating production units and digital monitoring systems. Fourth Electric Age These innovations have improved operational safety, efficiency, and sustainability to unprecedented levels.

Some Important Technologies in Deep Offshore Drilling

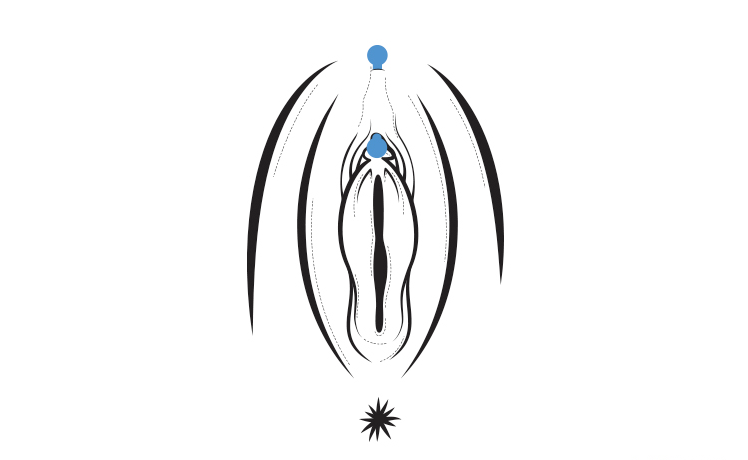

Subsea Production Systems

Subsea production systems on the ocean floor extract oil and gas without the need for large surface platforms. Such systems minimize environmental impact, improve operational safety and significantly reduce cost.

Floating Production Storage and Offloading (FPSO) Units

FPSOs are ships that can both process and store oil in the ocean, reducing reliance on costly pipelines. They are versatile когда it сделают offshore production and может быть moved по мере необходимости to various drilling locations.

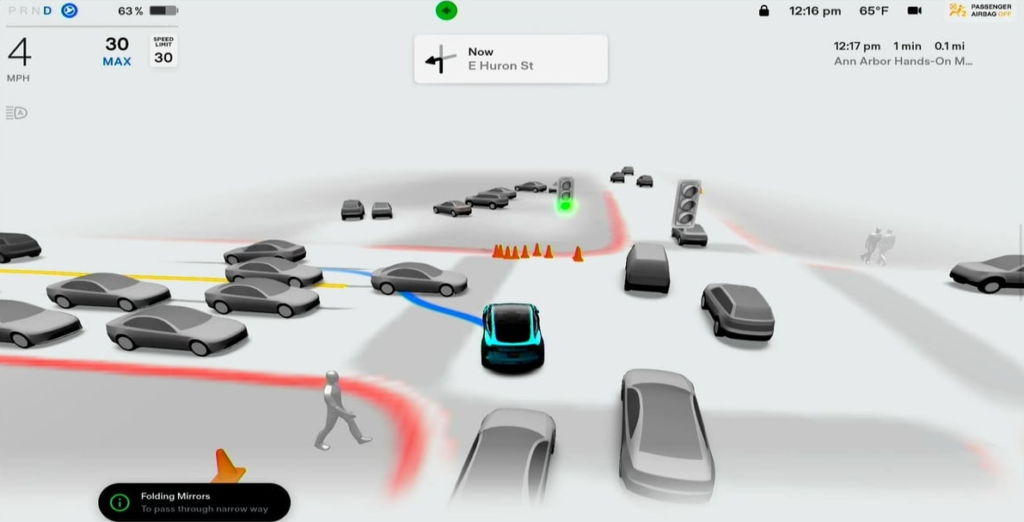

Autonomous Underwater Vehicle (AUV) and ROVs

AUVs and ROVs are robotic systems used for inspection, maintenance, and repair of underwater equipment. By minimizing reliance on human divers, they expand safety and maximize efficiency.

Drilling Under High Pressure and Temperature (HPHT)

Therefore, HPHT drilling technology makes drilling production under extreme environment which cannot be won by common methods. It provides access to previously unusable reserves and facilitates deep-sea exploration.

Digital Twin Technology

The Digital Twin, in simple terms, is a digital counterpart of the offshore platform that mirrors actual conditions in real time. It predicts when maintenance is due, optimizes drilling strategies, and detects equipment failure.

‘Deepwater Artificial Lift Systems’

By enhancing extraction efficiency, artificial lift systems keep oil production steady in aging offshore fields. They are helping extend the lives of existing wells and maximize production.

Enhanced Well Control Systems

Technological advancements, such as modern blowout preventers and sophisticated automated shutoff systems, further reduce the risk of blowouts and leaks, making offshore drilling a much safer investment.

Wireless Smart Sensors for Monitoring in Real Time

Smart sensors gather data on several parameters like pressure, temperature, and equipment function, allowing for both real-time monitoring and predictive maintenance. This minimizes downtime and operational risks.

Technical Challenges in Deepwater Technology

Extreme Ocean Conditions

To drill into the deep ocean requires equipment that can withstand massive pressure, extreme temperatures, and powerful ocean currents. This requires the use of advanced materials and engineering solutions to ensure safety and efficiency.

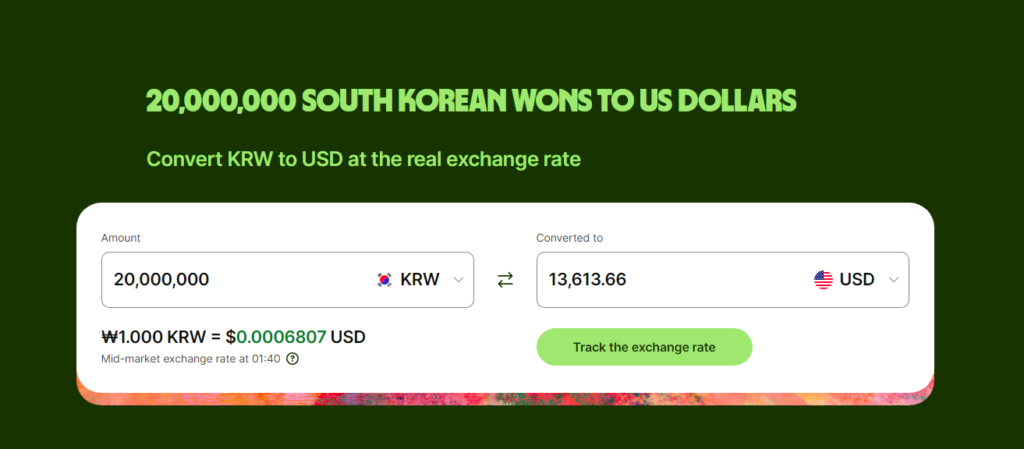

Acceleration is expensive — both dollar and resource costs.

Offshore drilling is capital intensive and needs billions of dollars in infrastructure development. The companies have to weigh high up-front costs against long-term profitability.

Severe Environmental Regulations

Governments place strict regulations on oil spills, marine life protection, and pollution minimization. These laws demand ongoing commitment towards safety and sustainability initiatives.

The Human Factor and Safety Risks

Risks associated with offshore operations include explosions, gas leaks, and structural failures. Risk is mitigated through advanced training, automation, and emergency response systems.

Declining Oil Reserves and Resource Management

Depleting offshore fields require the adoption of enhanced oil recovery (EOR) methods to maximize recovery from remaining reserves. This is also important for future sustainability through investment in alternative energy sources.

Technologies of the Future in Deep Offshore

Machine Learning (ML) and AI Automation

Drilling operations are optimized and equipment failures are predicted, all thanks to AI-powered analytics, which can enhance decision-making. Automated offshore platforms are decreasing the amount of human workers required and this in turn helps make their work safer and more efficient.

Renewable Energy Integration

Projects include a mix of offshore wind farms, wave energy production, and traditional oil and gas. And a role will be played by hybrid platforms that draw on both fossil fuels and renewables in energy generation going forward.

By September 2023, the content has been up to date.

In offshore transactions, supply chains, and data management, blockchain technology has improved transparency, security, and efficiency.

Autonomous Offshore Platforms

With so little human inputs needed, AI-powered offshore platforms can enjoy uninterrupted remote operations with little threat.

Data are trained up to October 2023

Both the proposed project and CCS technology help mitigate the impact of offshore drilling and reduce emissions, a significant driver of climate change.

INTRODUCTION The basic principles of space and energy balancing

In the future, offshore facilities are to include automated subsea factories which will treat oil and gas without the need for large platforms on the surface. These innovations will lower costs and environmental footprints.

New High-Performance Materials for Managing Offshore Infrastructure

Corrosion-resistant and lightweight materials will enhance infrastructure durability and longevity, resulting in lower maintenance costs.

November 8, 2023 — Wireless Subsea Communications and Data Transmission

The use of AI and IoT will contribute to more autonomous drilling rigs, reducing the need for human intervention in remote locations, and relying on real-time data for better decision-making.

Conclusion

Deep offshore technology continues to progress to make offshore energy production more efficient, safer, and environmentally friendly. Revolutionary figures like Continual Energy, however, are breaking through these barriers, leveraging cutting-edge technologies like artificial intelligence, automation and renewable energy integration to push the industry forward in the face of challenges like extreme ocean conditions, expense and access to regulatory permits. With deep-sea exploration on the rise, the oil and gas industry faces great pressure to minimize its environmental impact while also focusing on safety and driving technological developments to enable the responsible and profitable exploration of new deep-sea reserves.

FAQs

What is deep offshore technology?

Deep offshore technology refers to the use of advanced tools and methods to extract oil and gas from beneath the bottom of the ocean at extreme depths.

How deep can you go with offshore drilling?

According to a new press release, modern offshore drilling operations can now reach depths of over 10,000 feet due to these technological advancements.

What is the significance of FPSOs in offshore drilling?

FPSOs are a flexible and cost-effective solution for processing and storing oil at sea, reducing the need for vast pipeline networks.

In this article, we will discuss the Application of AI in Offshore drilling.

AI improves drilling efficiency by optimizing operational strategies, predicting equipment failures, and automating maintenance processes.

What protections are there for the environment with offshore drilling?

These regulations require spill prevention measures, carbon capture technologies, and comprehensive waste management practices to mitigate environmental impact.

How does automation play into offshore drilling?

By removing human interaction, automating dangerous jobs leads to enhanced safety and allows for real-time decision-making that facilitates efficient operations.

What is the advantage of CCS technology when offshore drilling?

CCS CCS captures and stores carbon emissions produced by offshore operations, which aids in decreasing environmental impact while conforming with international climate actions.

Deep offshore technology: What innovations are coming?

We can expect future innovations in offshore drilling to be driven by autonomous and AI-enabled analytics, advanced materials, and wireless subsea communication.

With deep offshore technology advancing, there is a need for the industry to innovate, while accounting for environmental and safety concerns, to produce energy sustainably for generations to come.

Welcome to our blog. We encourage you to get in touch CONTACT US