Deep Offshore Technology: Advancements, Challenges Prospects

Introduction: Deep Offshore Technology

The advent of deep offshore technology has transformed the process of exploring and obtaining resources from the deep seas. However, as demand for energy and raw materials grows, breakthroughs in deepwater drilling, robotics and sustainable solutions are ever-pushing the envelope in what can be achieved below the waves. This article shares the latest innovations, challenges, and the future of deep offshore technology.

What is Deep Offshore Technology?

Deep offshore technology is the plethora of engineering, equipment, and methods to engage in operations at sea in deep and ultra-deep waters, or typically at depths of more than 500 meters (1,640 ft). This technology is vital for the exploration and extraction of the oil, gas, and other resources that lie beneath the seabed. To satisfy the world’s burgeoning energy demands, deepwater operations have become pivotal in addressing these requirements whilst balancing efficiency and sustainability.

Highlight Developments in Deep Offshore Technology

Advancements in Deepwater Drilling

Floating production systems, Such as FPSOs, which enable efficient oil extraction and storage on an autonomous basis.

Deepwater Oil Extraction: Advanced marine systems require fewer surface-based facilities, allowing for direct on-the-bottom extraction.

This is referred to as Extended Reach Drilling ERD , which enables drilling at extreme angles to reach remote oil and gas reservoirs.

MPD-MPDR (Managed Pressure Drilling-Managed Pressure Drilling): A method for keeping the wellbore stable, minimizing the threat of blowouts, and optimizing the extraction of resources.

Robotics and Automation

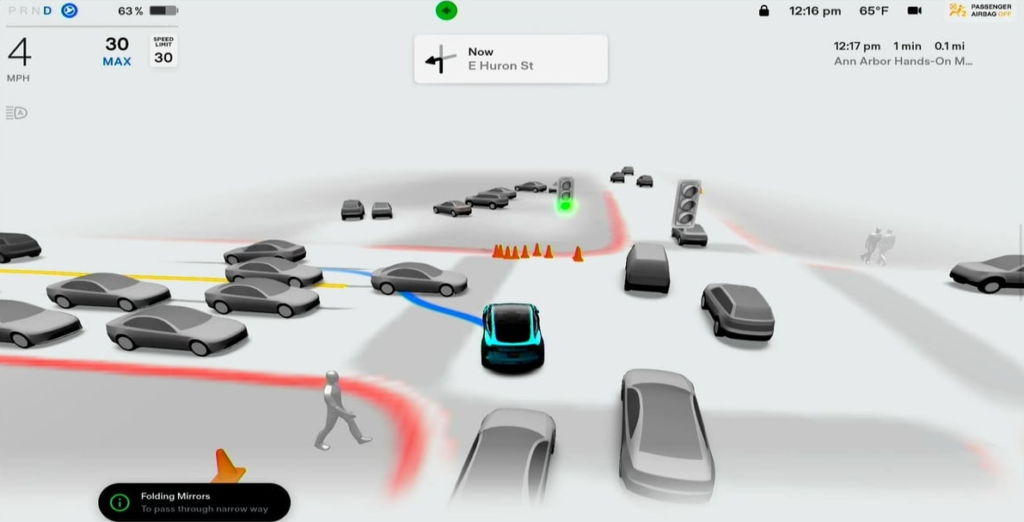

ROVs: Remotely Operated Vehicles are unmanned submarines that make deep-sea exploration, maintenance, and repairs easier.

Autonomous Underwater Vehicles (AUVs) – AUVs don’t rely on human supervision for control, and are integral for mapping and surveying tasks.

AI-Based Monitoring Systems: AI not only facilitates real-time decision-making but also minimizes human intervention in risky environments.

Anonymous-Overview: Data read in by digital twin technology provides virtual counterparts of the physical offshore components enabling predictive maintenance and operational improvements;

Materials Science and Technology

Corrosion-Resistant Alloys: These alloys make offshore structures last longer due to their capability of surviving at higher pressures and temperatures.

05: Flexible Risers and Pipelines: These resilient systems withstand ocean currents and adverse conditions, safely transporting extracted resources.

HPHT Technologies – Specialized equipment that works in extreme deep sea conditions.

self-healing materials, Innovative materials that can automatically heal minor damages in offshore structures, which would increase equity over the lifetime of the infrastructure.

Environmental Protection and Sustainability

Carbon Capture and Storage (CCS): CCS Technology for reducing carbon emissions from offshore drilling

Renewable Offshore Energy: Incorporation of offshore wind, wave, and solar energy in deep-sea operations.

Environmentally Safe Drilling Fluids: Biodegradable drilling options minimize ecological footprint.

Old Oil Well Decommissioning and Recycling Initiatives: Safely take down obsolete offshore structures and repurpose materials

Deep Offshore Technology Challenges

High Operational Costs

Deep offshore infrastructure takes time and money because it requires specialized equipment, expensive material, and requires advanced research and development of new technologies.

Yards of Growth: Harsh and Unpredictable Environments

Deep water exploration and production operations are subject to extreme pressure and low temperatures as well as unpredictable weather patterns that increase risks and maintenance demands.

Safety and Risk Management

Despite the advances of technology, the chance of blowouts, leaks, and structural failures are still a worry. We need better regulation around safety, more real-time monitoring systems, more gensets, sustainable solutions to the problem.

Employee and Environmental Regulatory Issues

Tough environmental regulations and sustainability targets add further complexity for offshore activities. Companies need to adhere to evolving international laws while switching to greener technologies.

offshore technology: Which is the future?

Innovation and sustainability are shaping the future of deep offshore technology. Key trends include:

More Automation and Smart System Integration: Human intervention extraction.

Subsea Factories for Fully Autonomous Operations

Expansion of Solutions for Renewable Offshore Energy

Stronger emphasis on lowering carbon footprint in offshore endeavors: Adoption of sustainable drilling techniques & emission reduction strategies

Using renewable energy in oil and gas operations to develop hybrid offshore energy systems

FAQs

What is deepwater drilling?

Deepwater drilling is the exploration of oil and gas in water more than 500 meters (1,640 feet) deep. Ultra-deepwater drilling is conducted at depths of greater than 1,500 meters (4,921 feet).

What does Offshore Technology do?

For example, ROVs perform deep-sea inspections, repairs, and data gathering without human divers. They are essential for infrastructure maintenance, safety inspections, and the exploration of new reserves.

Role of AI in Optimizing Deep Offshore Operations

By offering real-time monitoring, predictive maintenance, and autonomous system controls, AI increases efficiency and safety, while lowering operational costs.

What can sustainably replace offshore oil drilling?

Correct, offshore wind farms, wave energy and solar platforms are renewable energy opportunities that supplement fossil fuel extraction. Some oil and gas firms are incorporating these into existing operations.

What are some of the biggest risks involved in deep offshore drilling?

Some of these risks have been quite devastating: blowouts, structural failures, high operational costs, environmental hazards (e.g., oil spills, damage to the marine ecosystem, etc.).

Do offshore companies deal with environmental footprints?

Harvest energy for sustainable development. The companies use environmentally friendly drilling fluids, carbon capture technologies, and rehabilitation programs to limit their impact on the environment and achieve global sustainability objectives.

Why subsea production systems matter?

They allow efficient extraction of resources at the deep sea and lessen the environmental footprints by minimizing the need for surface platforms.

Conclusion

Deep offshore technology is constantly being improved, allowing us to explore underwater resources more safely, efficiently, and sustainably. As automation, materials, and renewable energy integration continue to grow and advance, the future of offshore operations appears to be promising. It balances a need for economic viability with a desire for environmental stewardship. Industry leaders must prioritize innovation and sustainability to ensure stability in the offshore sector as energy exploration dives deeper into the oceans.

Welcome to our blog. We encourage you to get in touch CONTACT US!